2017年2月27日星期一

QZ Type Grab Bucket Overhead Crane

#QZ Type Grab Bucket Overhead Crane

China Nucleon Crane Group

#Web http://www.nucleoncranegroup.com/qz-type-grab-bucket-overhead-crane.html

#Contact Skype:nucleoncranegroup OR Email:info@nucleoncranegroup.com

2017年2月20日星期一

2017年2月17日星期五

Engineering crane-nucleon crane group

Engineering crane-nucleon crane group

Engineering crane wire rope and its selection

The use of wire ropes in engineering cranes is very common and is generally made of many high strength steel wires. It is first formed by a single wire around the formation of shares, and then some of these stocks around the rope, and then by the other shares of the outer strand around the rope around the rope into a wire rope. Some of the imported wire rods also contain a plastic ferrule, usually in the form of plastic coating through a special treatment covered in the core, the important wire rope in the rope filled with the appropriate lubricant to reduce friction.

Domestic wire rope according to the core material is generally divided into organic matter (core and cotton core), asbestos core or metal core three, the rope is usually no filler or lubricant.

Wire rope by wire around the shares and shares around the rope into the direction of each other can be divided into a rope and around the rope, and according to its strand twist into the left and right with the twist and left and right twist; Generally to wrap around the rope as the standard, the provisions of the wire rope and the rotation relative to the vertical axis of the rope as the base of the outer spiral of the same line, divided into left and right. Correspondingly, the rotation of the strands is defined, that is, the direction of the helix of the outer strands of the constituent stocks is the rotation of each strand, based on the longitudinal axis of the strands. Ordinary wire rope in a single use, have to wire rope in the opposite direction of rotation of the phenomenon, in the pulley group will be used when the wire rope rotation caused by lifting wire rope twist, commonly known as twisted. Relative to the ordinary wire rope, the current does not rotate the wire rope has begun a large number of applications. The so-called non-rotating wire rope is based on the principle that the rope and the torsion torque of the opposite direction and the size of the same: the import does not rotate the wire rope is different, the principle is to make the rope and the rotation of the rope itself, Force, the core of the torque generated by the external shares and the torque generated by the same size, the opposite direction.

The strand of the wire rope can also become a tight stock by rolling or die extrusion, etc. The diameter of the treated strand will be reduced and the surface finish will be high. Therefore, the use of tight wire rope can use thicker wire, the same diameter, the use of tight strand wire rope filling factor is higher, breaking tension greatly improved. When the multi-layer winding on the reel, the ordinary shares of the wire rope its outer shares in the layer and the layer between the more serious extrusion, wire rope surface wear faster. While the tight strand of the wire rope has a high resistance to wear and anti-extrusion capacity.

The choice of wire rope is correct or not, directly affect the life of the rope and the rope to produce structural deformation, fracture and accidental failure. Therefore, the recommended principle is as follows:

1) When a non-oriented weight is raised or at a large height for multiple non-guided lifting, the non-rotating wire rope is used:

2) Ordinary steel wire rope can be used when a guided lifting is carried out or a plurality of guided lifting (such as driving) or left and right spin strands are used in pairs at a small height.

Wire rope rotation should be determined to follow:

The right-handed rope groove is recommended for the use of the left-handed wire rope: the other hand, the left-hand rope groove reel should use the right-hand wire rope.

For single-layer winding non-rotating wire rope, must strictly abide by the above principles, or easy to cause permanent deformation of the rope structure; for multi-layer winding situation, the rope from the direction of the drum rope groove to determine the direction of the next layer to play Good foundation.

Multi-layer reel of the wire rope between the friction and the pressure is greater, easy to produce rope phenomenon, it should be used slightly smaller than the diameter of the rope groove and rope groove diameter wire rope to increase the wire rope and reel The contact area between the adjacent wire rope to reduce the friction between the wire rope to improve the life. Practice has proved that the diameter of the wire rope than the groove pitch 1% smaller, contribute to the tight row of rope, effectively eliminate the climb rope, rope phenomenon.

In the same diameter, the more the number of strands of wire rope, the more the smaller the diameter, the thinner the single wire, the flexibility of the wire rope, can be a good way to overcome the wire rope into the reel when the reverse bending force , Wearing a rope is also easy. While the thick outer shares, the wire is also thick, you can better resist wear, mechanical damage, corrosion and squeezing force. Therefore, only the two advantages of a good combination, is the real high-performance high-quality wire rope.

In addition, the wire rope in the selection process also pay attention to its minimum diameter and minimum breaking tension should be consistent with the provisions of ISO4308 standard.

- See more at: http://www.nucleoncranegroup.com/engineering-crane.html

2017年2月16日星期四

2017年2月13日星期一

china nucleon crane group: frequency conversion overhead traveling crane

china nucleon crane group: frequency conversion overhead traveling crane: frequency conversion overhead traveling crane Application of frequency conversion speed regulation in overhead traveling crane First...

frequency conversion overhead traveling crane

frequency conversion overhead traveling crane

Application of frequency conversion speed regulation in overhead traveling crane

First, brief description of the overhead crane

The bridge crane is currently widely used in industrial and mining enterprises in a lifting hoisting equipment. It is generally divided into three basic mechanisms: for lifting heavy lifting mechanism, for lateral movement mechanism for moving heavy objects (i.e. bridge crane car movement organization) and for the longitudinally moving heavy objects (i.e. bridge the crane traveling mechanism)

Where in the hoisting mechanism of the overhead traveling crane is to control the reversing of the three-phase asynchronous motor, and the reel is driven by the coupling and the reducer to raise or lower the wire rope. The bridge crane two mobile agencies, respectively, by controlling the three-phase asynchronous motor positive and negative, through the coupling and reducer drive wheel rotation.

Second, the bridge crane frequency control of the overview

Bridge crane frequency control principle: In the asynchronous motor of the number of pairs of p and slip s of a certain circumstances, only to change the power supply frequency of the asynchronous motor f, can achieve the speed of the asynchronous motor. However, when the power supply frequency f is less than the rated operating frequency of the motor changes, the terminal voltage U ≈ (where: E1-induced electromotive force, f-power supply frequency, w-series turns, k-winding coefficient, φ-motor Of the flux), only to maintain U / f constant, in order to ensure that the motor flux φ unchanged to ensure that the motor performance unchanged. And when the power supply frequency f is greater than the rated operating frequency of the motor, the motor speed exceeds the rated speed, if still maintain U / f constant, the terminal voltage U will exceed the rated motor voltage, which is not allowed, therefore, the rated speed , The power supply voltage should be kept constant and rated, only increase the frequency f of the power supply, the motor flux φ will be reduced, the output torque will also be decreased, while the output power is approximately constant.

Bridge crane frequency control mode is generally used U / f control, vector control and direct torque control. Hoisting mechanism of the crane which uses a closed-loop vector control or closed-loop direct torque control; and mobile institutions generally open-loop U / f control mode or open-loop vector control mode.

Bridge crane frequency control is generally divided into hoisting agencies variable frequency speed control and mobile agencies, mainly by the organization of the inverter motor, inverter, control devices and line protection switches and other components. However, in order to prevent the inverter interference to the outside world and their protection, and improve the accuracy of motor control, generally in the inverter around with AC / DC reactor, the brake unit and braking resistor, filter and transmission card pieces, etc. . Which, according to the use of different overhead crane mechanism, the hoisting mechanism used in the variable frequency motor are equipped with optical rotary encoder to improve speed accuracy and response speed. At the same time control devices using PLC and relay combined to replace the past, the use of AC contactor control, the control system reliability, flexible application, the line is simple, easy to use and low failure rate.

For more details, please contact us via info@nucleoncranegroup.com

- See more at: http://www.nucleoncranegroup.com/frequency-conversion-overhead-traveling-crane.html

For more details, please contact us via info@nucleoncranegroup.com

320Ton Overhead Crane for Casting

320Ton Overhead Crane for Casting

China Nucleon Crane Group

#Web http://www.nucleoncranegroup.com/double-girder-overhead-crane.html

#Contact Skype:nucleoncranegroup OR Email:info@nucleoncranegroup.com

2017年2月3日星期五

china nucleon crane group: Electric Hoist Lifting Heavy Load

china nucleon crane group: Electric Hoist Lifting Heavy Load: Electric Hoist Lifting Heavy Load The Reason of Wire Rope Electric Hoist Can not Obliquely Lifting Heavy Load The drawing of electric ...

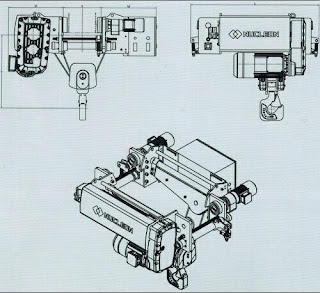

Electric Hoist Lifting Heavy Load

Electric Hoist Lifting Heavy Load

The Reason of Wire Rope Electric Hoist Can not Obliquely Lifting Heavy Load

|

| The drawing of electric hoist |

Wire rope electric hoist can not be inclined hanging heavy objects, why? From the perspective of our physical mechanics!

Junior high school physics class we learned a knowledge point that: If you want to bring a heavy object, are brought him straight up, if the ramp, then the power consumption of more, but also not smooth, in fact, the reason for the wire rope Electric hoist on the same applies.

Lifting heavy objects in the wire rope hoist, we also require a vertical lifting, do not oblique hanging cable, if oblique hanging cable,will not only make heavy objects swing or collide with other objects, but also cause broken rope, Overload, and even heavy objects such as falling, resulting in immeasurable losses. If the wire rope is squeezed in the reel shell or fall outside the pulley, the inclined cable-stayed cable will be squeezed bad; if the weight of the pulled objects, but also the phenomenon of wire rope fracture. This is very dangerous.

A weight of P kg, placed on the ground, such as the vertical lifting, with the same force N or slightly larger than N force, heavy objects can leave the ground. However, such as the use of wire rope ramp (pull S and the ground perpendicular to the line into a α angle), in order to lift heavy objects, the wire rope S will be much greater than the weight of P Caixing. This is why?

According to the law of the decomposition of the force, the tension S can be decomposed into a vertical component force N and a horizontal component F. As can be seen, S> N, because the requirements of N = P, so S> P. That is, the slant crane wire rope tension than the weight of heavy objects, and the larger the angle α hanging angle, S is also greater. Ramp will produce overload, is this truth.

In addition, due to the ramp to produce a horizontal component of force F, when the weight off the ground, F force will drive the weight to the vertical center of gravity swing, if at this time close to the other objects can touch. This is not another important reason for the ramp.

Through the above example analysis, I believe we will be able to understand why the wire rope electric hoist is not inclined hanging ramp, but also to remind you in the use of the user must comply with the procedures for operation.

For more details, please contact us via info@nucleoncranegroup.com

- See more at: http://www.nucleoncranegroup.com/electric-hoist-lifting-heavy-load.htmlCD electric hoist-nucleon crane group

CD electric hoist-nucleon crane group

CD electric hoist

CD electric hoist low price, widely used in warehouses

The advantage of the electric hoist made of Nucleon crane group is: easy to operate simple, fast speed, wire rope length can be customized according to customer demand, in order to increase product safety, also set the limit switch, low price, can be widely Used in factory warehouses, logistics, freight and other occasions.

Nucleon wire rope electric hoist with a safe brake device to ensure that the goods in the lifting process of unexpected power failure, can also ensure the safety of lifting material. Electric hoist excellent rope guide to solve the lifting process of swinging items. With the road and electric sports car to meet your needs on different occasions Nucleon imported chain electric hoist all imported from Taiwan and Japan, the products are in accordance with international standards of production, electric chain hoist body with a chain frame to ensure that the chain in the rise And when the chain will not be the case of the chain of cards will not lead to the work of the interruption or cited the situation occurred Nucleon lifting welcome new and old customers to negotiate to buy.

Nucleon lifting electric wire rope hoist mainly CD1 and MD type two. They have different characteristics, CD-type wire rope hoist to enhance speed, up to 8 meters per minute. CD-type electric hoist using high-quality braking system to ensure that even if the power lifting process will not cause security incidents. CD electric hoist with aluminum radiator, heat dissipation is particularly good, it can withstand long hours of high-intensity work, upper and lower limit switch to ensure that the rope does not reverse the situation.

The use of wire rope electric hoist can greatly improve the production efficiency and reduce labor, help to improve the company’s costs and improve corporate income.

- See more at: http://www.nucleoncranegroup.com/cd-electric-hoist.html

2017年2月2日星期四

订阅:

博文 (Atom)